FUCINA ITALIA, FUCINA OF IDEAS…

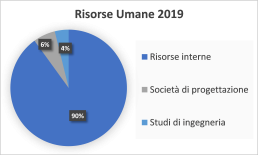

Since 2019, the new ownership of FUCINA ITALIA srl has undertaken applied research, experimental development and innovation activities.

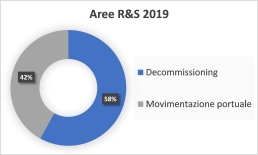

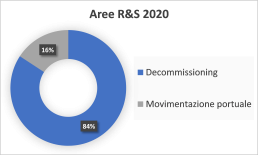

Thanks to its in-house team of qualified engineers, expert designers and highly specialized workforce, FUCINA ITALIA has defined two areas on which to focus its R&D activities: decommissioning and port handling.

The R&D projects undertaken, born from production needs and objectives, thanks to the strong integration between the various company functions, have contributed to the growth and enhancement of the stock of knowledge not only of the personnel involved but of the entire company.

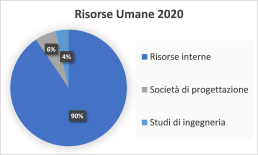

In 2020, FUCINA ITALIA increased its investment in R&D by over 70%, keeping the distribution of human resources constant, focusing on projects related to decommissioning and consolidating the excellent results in the port handling sector.

Internal investment has further contributed to the drive for growth and change that permeates the consolidated corporate culture and allows FUCINA ITALIA to increasingly offer itself, in the selective reference market, as a reliable partner and always ready for new challenges.

FUCINA ITALIA R&D projects in numbers – Total investment 2019 € 195,391.49

FUCINA ITALIA R&D projects in numbers – Total investment 2020 € 350,484.25

Human Resources 2019

R&D Areas 2019

R&S Areas 2020

Human Resources 2020

TECHNICAL DEPARTMENT, AT YOUR DISPOSAL

The Technical Department of FUCINA ITALIA combines the experience and reliability of over twenty years of activity, with the speed and precision brought by the most modern and powerful 3D calculation and design software.

The group, made up of mechanical and electrical engineers, designers and high-level technicians, has concluded over the years projects and patents with excellent results and feedback in the following main sectors:

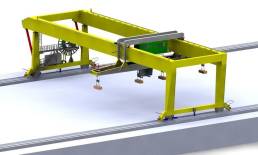

- Lifting machines and accessories (cranes, bridge cranes, special accessories)

- Machines and equipment for port unloading (multifunctional sleepers, lifting beams, accessories and prototypes for cellulose unloading)

- Boilers / pressure vessels

- Industrial carpentry

- Radioactive waste storage tanks

- Hazardous materials storage facilities

The services we offer are:

- Feasibility studies and preliminary design starting from the customer’s ideas / needs and needs

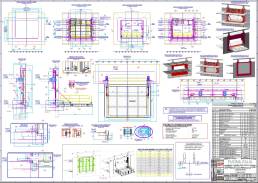

- Functional, Executive and Construction Design (calculation dossier and construction drawings)

- Manuals

The main software used, constantly updated, are:

- SOLIDWORKS – Nr. 6 PROFESSIONAL licenses (for 3d drawing) + Nr. 3 PREMIUM licenses (with analysis and calculation software)

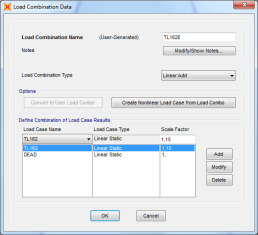

- SAP 2000

- AUTOCAD – nr. 10 2d drawing licenses

- COMPOSER – for manuals

- ALYANTE (TEAMSYSTEM) for administrative, commercial management and project analysis.

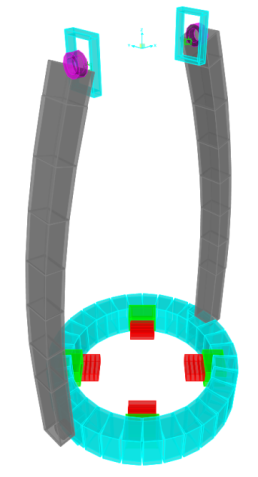

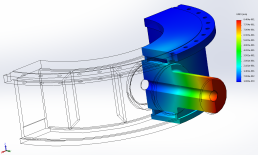

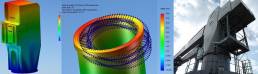

FINITE ELEMENTS CALCULATION – SAP 2000

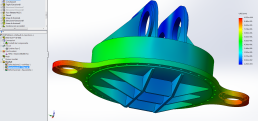

FINITE ELEMENTS CALCULATION – SOLIDWORKS SIMULATION

3D MODELS – SOLIDWORKS

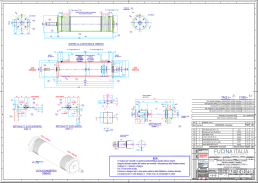

PLACED ON THE TABLE – AUTOCAD/SOLIDWORKS

SMALL TOLERANCES ON LARGE PRODUCTS

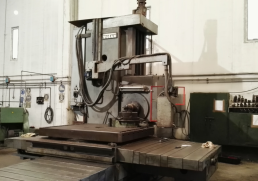

Our mechanical workshop allows us to create more or less complex components, for single supplies, in series or for the final processing of welded compounds coming from the carpentry department.

Our strengths are:

- Close collaboration between carpentry and mechanical workshop

- Specialization of the workers

- Possibility of working large items thanks to the spaces of the workshops and large machine tools

In addition to the traditional workshop machines, the typical machines at our disposal are:

Farrell CNC Z32 boring machine

Capacity 100ton

Stroke X 12000mm

Y-stroke 3350mm

Spark plug stroke 1900mm (Depth)

Wotan boring machine

Stroke = 1500mm x 1500mm x 1500mm

Turntable = 2000mm x 2000mm

Spark plug diameter = 130mm

Spark plug stroke z = 800mm

Maximum capacity of the rotary table = 20t

Induma cutter

Stroke = 900mm x 550mm x 400mm

Clovis 70 lathe

Turning diameter above the carriage = 950mm

Spindle diameter = 1200mm

Turning length L=6000mm

Maximum capacity = 16t on tips

N.2 traditional lathes

Turning diameter above the carriage = 400mm

Turning length = 3000mm

Maximum capacity = 8t on tips

For the machining of small components, for mass production and for requests for special machining and finishing on small components, we make use of consolidated partners, equipped with numerical control machines, with whom we have been collaborating for many years.

WELDING: “FUCINA ITALIA” LEADING SECTOR

Welding is one of the most important activities for the sectors in which we operate.

The high level of automation, the use of the best machinery on the market, equipped with cutting-edge technological systems, the high professionalism of the operators and NDT staff and, last but not least, the presence of an IWE (International Welding Engineer) Certified Welding Coordinator have allowed to:

- Achieving a high and rich know-how

- Obtain numerous qualifications

- Certify operators for welding with the various processes listed below.

The processes are certified according to UNI EN ISO 15614-1 and 7, UNI EN ISO 15613, EN ISO 17660-1 and ASME IX. The Operators are certified according to UNI EN ISO 9606, UNI EN ISO 14732 and ASME IX.

Certified welding processes

- TIG WELDING

Tungsten Arc Welding

- GTAW WELDING

Gas Tungsten Arc Welding

- MIG WELDING

Metal-arc Inert Gas

- MAG WELDING

Metal-arc Active Gas)

- GMAW WELDING

Gas Metal Arc Welding

- WELDING COATED OR SMAW ELECTRODE

Shielded Metal Arc Welding

- SUMMERSED ARC OR SAW WELDING

Submerged Arc Welding

- WELDING SURFACE WO ESW

Welding Overlay Electro Slag Welding

- WO MIG WELDING OVERLAY

Welding Overlay MIG (Metal-arc Inert Gas)

Main materials covered by the owned welding processes

- CARBON STEELS (structural)

- BOILER STEELS

- STAINLESS STEEL 300 series

NiCr ALLOYS (Ex. Alloy UNS N06022).

For the welding overlays the materials used are those of the 300 series (such as 308, 309 or 316), the NiCr alloy (such as UNS N06022 and UNS N06625) and CoCr (such as Stellite 21).

Non-destructive testing

Fucina Italia has certified internal operators to perform NDT checks for UNI EN ISO 9712 and ASNT SNT-TC-1A systems for VT, PT MT and RT-L methods.

In detail, the TESTING & FUCINA ITALIA QUALITY is composed of a 2nd level certified for non-destructive testing in VT, MT, PT, RT-L methods assisted by a test operator and supported by the external Welding Coordinator having III level on VT, PT, MT, RT, UT, UTTOFD and Phased Array, TT.

Welding machines

- N.1 LINCOLN MH 60.4 MANIPULATOR

TECHNICAL SPECIFICATIONS

Useful column translation: 5.000mm

Useful beam translation: 6.000mm

Total manipulator height from the ground

Beam lifting speed __1.000mm/min

Beam translation speed ________ 180-1.800mm/min

Base movement speed ____180-3.000mm/min

- N.1 LINCOLN IDEAL ARC 1000 (mod. 9547) – SAW

TECHNICAL SPECIFICATIONS

Useful column translation: 4.000mm

Useful beam translation: 4.000mm

Carriage stroke: 20.000mm (up to 50.000mm)

Generator Dc 1000A with head na3

- N.1 LINCOLN IDEAL ARC 1000 – SAW

TECHNICAL SPECIFICATIONS

Useful column translation: 5.000mm

Useful beam translation: 4.500mm

Carriage stroke: </ 2.000mm

Generator __ Dc 1000A with head na3

Welders

- FRONIUS VR 4000 – MIG/MAG

- No. 3 FRONIUS TPS 500I – MIG/MAG

- FRONIUS VR4000 TRANS PLUS SYNERGIG 5000 – MIG/MAG

- EVM PHOENIX 521 – MIG/MAG

- AIR LIQUID SAF 480 TRI – MIG/MAG

- SAF FRO DIGI WAVE 500 – MIG/MAG

- MILLER ROD 3 – MMA

- EWM TETRIX 350 DC/AC -TIG

- WELD FORCE KEMPII KSC 4500 – MIG/MAG

- SAF FRO BUFFALO 500 – MMA

- MILLER XMT 304CC/CV – MMA

- MILLER DINASTY 400 – MMA

- LOKERMANN GRAN MIG 501 MULTI SYN – MIG/MAG

• JASIC ITALIA 400P – MIG/MAG

STEEL FLOWS THROUGH OUR VEINS…

In our 4000m2 shed, used for carpentry work, custom-made products are made; our flexibility allows us to range from the heavy iron and steel industry to structures for handling in port areas, from open carpentry to pressure tanks, from bridge cranes to drums for the disposal of radioactive waste; in essence, our production area extends to accommodate the requests of all industrial sectors.

In addition to the traditional carpentry and bridge crane machines with capacities from a minimum of 12 to a maximum of 63+20 tons, the main machines, characteristic in terms of size and capacity, in our possession are:

Calandra Froriep

Maximum thickness 50mm

Maximum width 4m

Press

Workforce 500 tons

Colgar folder

400mP workforce

NUCLEAR DECOMMISSIONING

Nuclear decommissioning includes all operations aimed at the complete decommissioning and safety of industrial facilities and plants belonging to the nuclear chain. The experience gained over the years in this sector has allowed us over time to be involved in the front line in the design and construction of facilities designed and built for the following main purposes:

- Decommissioning of decommissioned nuclear facilities;

- Inertization of liquid and solid radioactive waste

The acquired know-how therefore makes us a highly competent partner and “problem solver”, able to range from the feasibility study to the concrete realization of the process and related plant engineering such as:

- Dynamic confinement of contaminated areas;

- Drainage and handling of radioactive liquid effluents;

- Environmental and online radiological monitoring.

THE DRAWING THAT BECOMES MATERIAL

To increase and speed up the production phase, FUCINA ITALIA can boast, within its fleet of equipment, a new sheet metal cutting machine capable of operating in oxy-fuel or plasma cutting mode based on the need or less than making cuts of greater precision and quality.

The main features of the machine are:

AUTOMATIC CUTTING MACHINE – DAMI MODEL HD 5500

Useful cutting width 3050mm

Useful cutting length 12200mm

External cartridge suction filter

SANDBLASTING AND PAINTING DEPARTMENT: AN ESSENTIAL SECTOR FOR FUCINA ITALIA

With a useful opening of 6x6m and a length of 40m, the Sandblasting/Painting area, equipped with sand recovery and continuous aspirators with special bag filters, allows you to accommodate small and large artifacts, guaranteeing optimal results in a short time.

The sandblasting treatment is one of the most used methods before a painting process; the large or small pieces are hit by a vast range of abrasive materials, depending on the type of result to be obtained, in order to bring them back to white metal.

The painting is applied in liquid with compressed air.

To guarantee the procedure, process and final painting quality checks are carried out by the Frosio III level inspector, with the release of supervision and inspection certificates to the customer with measurements and adherence tests.